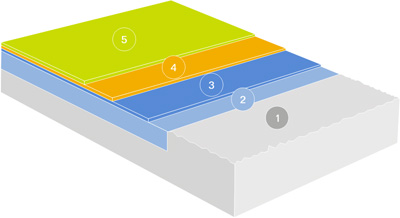

Polyurethane application Step by Step

Multiple applications exist for DESMOPOL , the section " Systems of Application " details the most frequent, nevertheless in all of them it is necessary to bear in mind a series of technical aspects in order for an ideal final result. Next we show the correct way of realizing a standard application.

-

SUBSTRATE

To apply DESMOPOL the substrate must be a continuous surface without crevices or hollows in order to obtain the maximum adhesion of the continuous system of polyurethane. Also the substrate must be clean, dry and free of pollutants like dust, oil, grease, paint and other superficial treatments. When in doubt it is recommended that you realize tests on the substrate.

-

Preparation of the support

CONCRETE SUBSTRATESThe substrate should be consistent as our membranes have adhesion strengths of up to 1.85 N/mm2 (MPa). If you are not certain of the strength you should inspect the substrate and, where possible, carry out tests to determine the tensile strength.

If there is a weak layer of cement on the substrate or it has an uneven surface you should prepare it mechanically (milling, sanding, shot-blasting).

If there are any cracks or small holes they should be filled in and compacted with the appropriate filling, made using our PRIMER EP-1020 product which is very hard and fast drying.

Specific areas, such as structural joints and perimeter flashings with walls, should be prepared using DESMOSEAL MASILLA-PU putty and/or TECNOBAND 100 ask our technical department. When all the preliminary work to prepare the substrate has been completed you should clean the area, clearing away any debris or loose material.

METAL SURFACES

The surface should be cleaned by applying our DILUYENTE TEC-4U solvent to ensure fast evaporation and drying. In the areas with overlaps, or the finishes of mechanical roof elements, we recommend using TECNOBAND 100 and/or DESMOSEAL MASILLA-PU putty to absorb the mechanical loads that are generated in this type of roof (ask our technical department).Please contact Tecnopol Sistemas technical department if you have any queries about other types of substrate (fiber cement, wood, asphalt, ...).

-

Priming

You should also apply one of our primers to increase adhesion to the substrate and achieve a correct surface finish. It can be applied by brush, roller or an airless spray.

In the case of concrete surfaces, the concrete should have completed the 28-day curing process after casting. You should also check that the degree of moisture in the surface of the substrate does not exceed the maximum allowable level of the product.

- Surfaces Porous (concrete): PU-1050 PRIMER / PUc-1050 PRIMER

- Surfaces Not porous (metal, ceramics, plates, asphalt, wood...): EPw-1070

-

Desmopol Membrane

DESMOPOL can be applied using a spray machine capable of producing a pressure of 280 bar (4,000 psi) or by hand, using a brush or a roller and a rubber rake. In both cases application must be consistent.

- Drying tact time: 3 ~ 5 hours*

- Pedestrian traffic resistance: 12 ~ 48 hours

- Wheeled traffic resistance: top coat required

- Repainting rank: 5 ~ 48 hours** / 3 ~ 24 h. (with D.ACELERADOR)

* In the case of low environmental temperatures, use DESMOPOL ACCELERADOR.

** If you want to apply a second coat of DESMOPOL and more than 48 hours 24h with DESMOPOL ACELERADOR have elapsed since the first coat of DESMOPOL was applied, the surface should be sanded and cleaned, and a primer coat of PRIMER EPW-1070 applied.

-

Top Coat (optional)

After the DESMOPOL membrane has been applied a protective coat of TECNOTOP aliphatic polyurethane varnish (see table b) should be applied within 48 hours (24h with DESMOPOL ACELERADOR), to ensure the stability of the desired colour when there is no additional protection. TECNOTOP is also good for surfaces with heavy vehicle traffic, and essential for non-slip finishes and waterproofing of swimming pools, fountains, water tanks, aquariums, etc.